Located just 30 minutes west of Atlanta, in Dallas, GA, Top Flight Aerostructures is an aerospace manufacturing and repair company that specializes in the manufacture of aerospace composites and adhesively bonded components of military aircraft structures. We have expertise in areas from CNC machining, to complex sheet metal fabrication, to advanced composite and metal-bonded panels, to classic sheet metal assembly and repair.

Top Flight Aerostructures is a small business, established in 2005, focused on quality and customer service. No project is too big or too small for the diverse capabilities of Top Flight.

Our highly skilled and motivated work force takes pride in exceeding our customer’s expectations.

SCOPE

Manufacturing, Repair and Engineering Services for Military and Commercial Aircraft Structures

and other Industrial Composite Applications.

OUR CAPABILITIES

facility

Top Flight Aerostructures operates a 40,000 square foot production facility located in Dallas, GA, just 30 minutes west of the metro-Atlanta, Georgia. Here we support the exacting requirements of new manufacture and repair to the detailed requirements of the drawings and supporting specification for with in-house capabilities and a highly skilled and motivated work force.

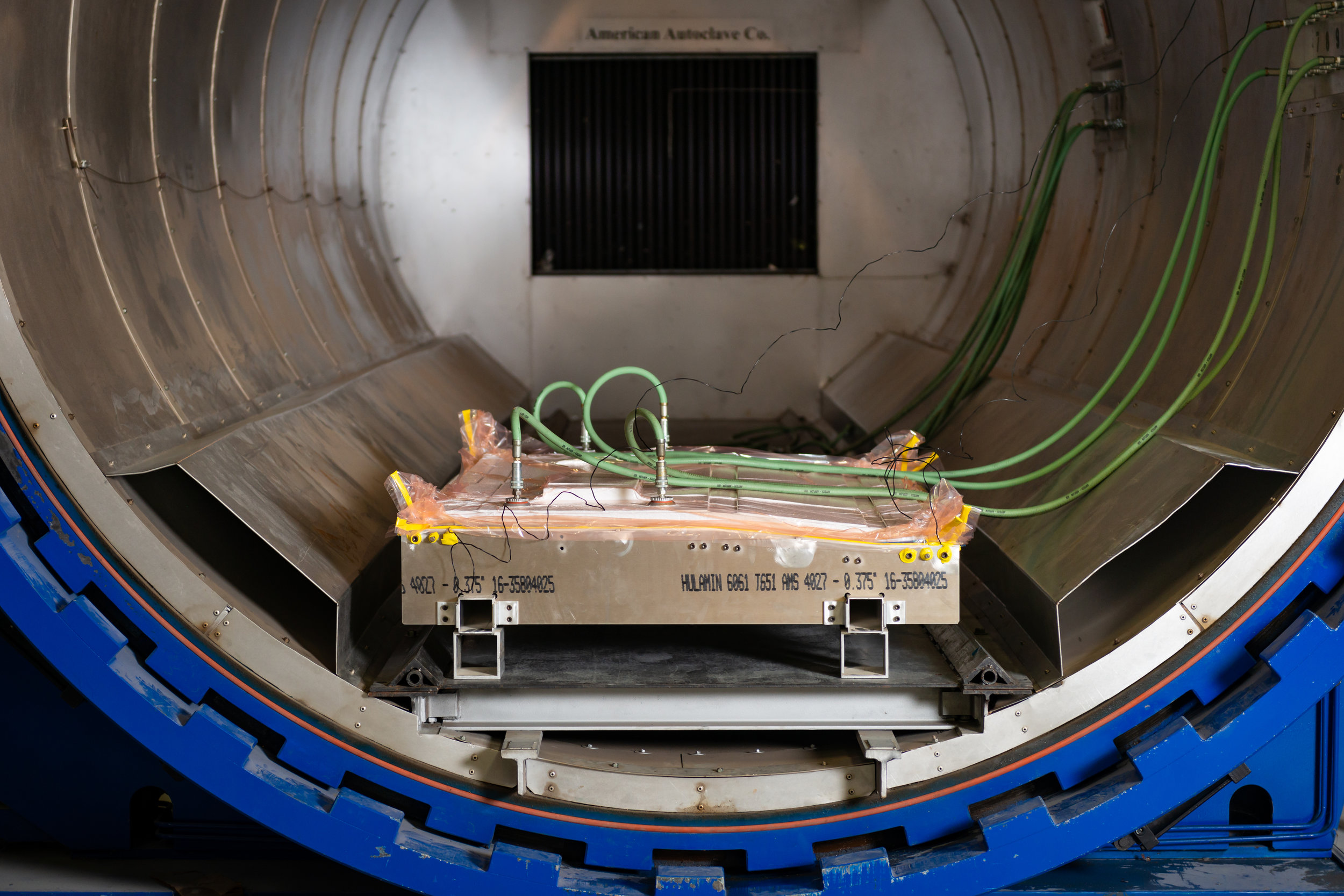

BONDING

Clean Room 1: 3310 square foot, temperature and humidity controlled

Clean Room 2: 348 square foot, temperature and humidity controlled

Autoclave 1– 5’ Dia x 10’ length, 450F, 150 PSI

Autoclave 2– 10’ Dia x 30’ length, 450F, 100 PSI

Autoclave 3 - 2’ Dia x 3’ length, 450F, 100 PSI

Walk-in Freezer – 11’ wide x 8’ tall x 13’ deep

Oven 1 – 4’ wide x 4’ tall x 8’ deep

Oven 2 – 8’ wide x 7’ tall x 16’ deep

Prepreg and metal bond fabrication

Aluminum, Nomex, fiberglass honeycomb

Polyurethane and Rohacell core forming and fabrication

Resin infusion and wet layup

3 Aligned Vision laser ply projectors

Ply cutter

precision machining

Fadal VMC 6030HT, Model 907-1 3-axis vertical milling center: Work envelope 30” x 62” x 30”

Haas TM-1 3-axis vertical milling center: Work envelope 30” x 12” x 16”

Thermwood C67 5-axis router: Table size 5’ x 10’

MasterCam programming software

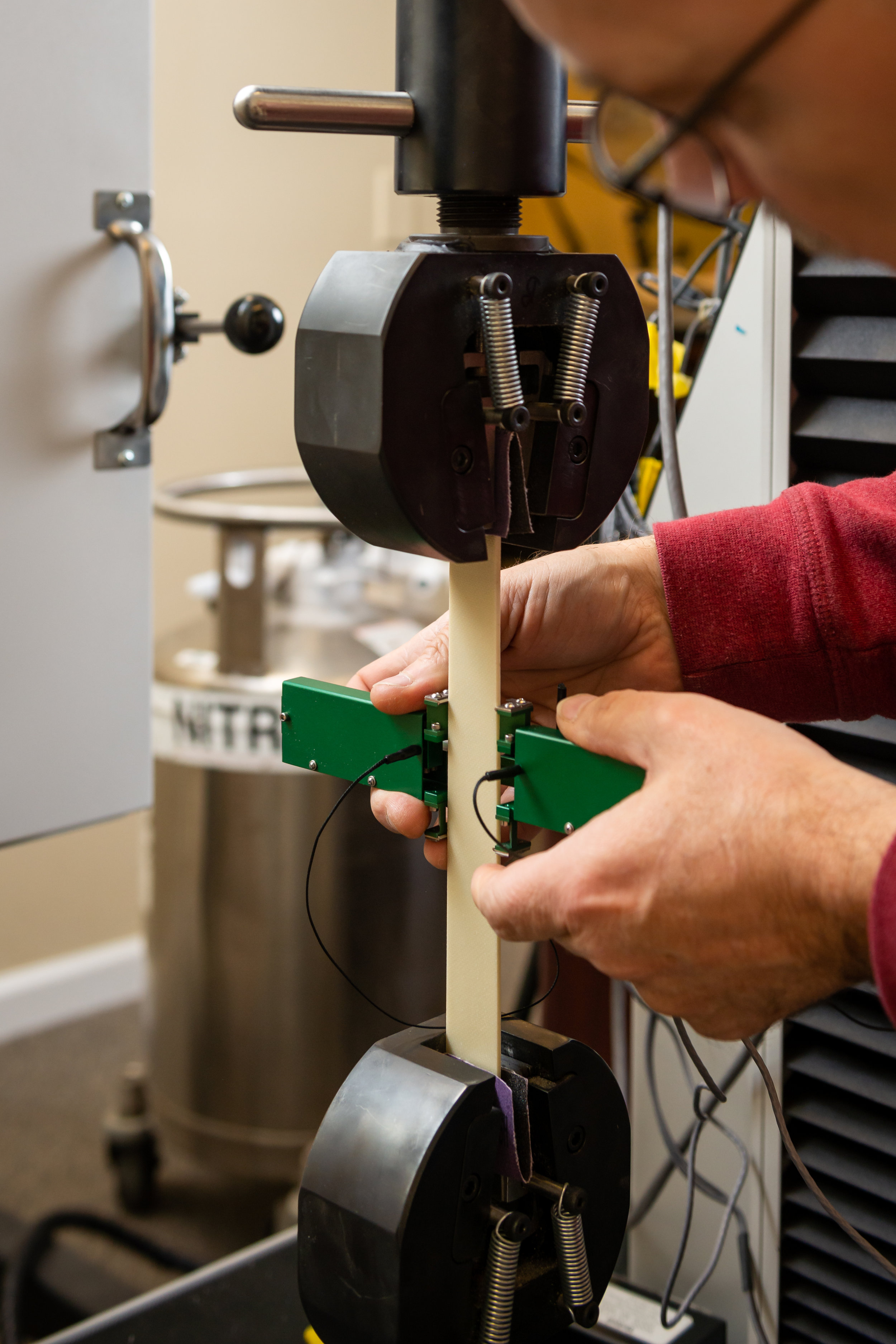

INSPECTION AND TESTING

United "Smart1" Floor Model Electromechanical Testing Machine, and United Environmental Chamber

Thermotron environmental conditioning chamber

Olympus Nortec 500C eddy current and conductivity tester

Creaform HandySCAN 700 Portable 3D scanner

Creaform MaxShot photogrammetry

VXelements (VXmodel and VXinspect)

API Radian Plus Laser Tracker with vProbe

VeriSurf inspection software

Platinum FARO Arm, 5’ radius, portable CMM

CAM2 inspection software

SHEET METAL

10’ sheet metal power shear

10’ sheet metal brake

40” sheet metal roller

English Wheel contouring equipment

Grieve AG-1000 aluminum heat treat oven, 36” x 48” x 36”

finishing

Paint Booth – 24’ x 14’ x 9’

engineering

SolidWorks 3D CAD, CFD, FEA

Rhino 3D CAD

Femap/NASTRAN FEA

Full material characterization (RTD, CTD, ETW)

Digital image correlation

Laser scanning

Contour inspection

Full tooling design and development

YOU ARE ENTERING A CULTURE OF QUALITY

QUALITY POLICY STATEMENT

Top Management hereby commits to being the industry leading provider of aerospace engineering, parts, and assemblies. Top Flight Aerostructures maintains a commitment of continuously improving to ensure integrity in quality, pricing, delivery, and customer satisfaction.

QUALITY MANAGEMENT SYSTEM

MEET OUR TEAM

BILL VISAGE

PRESIDENT

-

Bill is co-founder and has been serving as the company President since 2005. Bill is overall responsible for the business operations and business development. Bill is an aerospace engineer with over 25 years of engineering and aircraft structures experience, both commercial and military. Technical expertise includes metal-bond and composite component overhaul, repair, and new manufacture. Prior to working with Top Flight Aerostrutures, he worked for 10+ years at Delta Air Lines as an Engineering Supervisor for structural component repair. Bill holds a Bachelor of Science in Aerospace Engineering from the University of Virginia and currently serves on the Advisory Boards for the Georgia Tech Manufacturing Extension Program and the Paulding College and Career Academy. Bill enjoys spending his free time with his wife and three kids.

GREG KRESS

VICE PRESIDENT

-

Greg is co-founder and has been serving as company Vice President since 2005. Greg is a recognized industry Subject Matter Expert in Composites. Greg is an aeronautical engineer with over 30 years of engineering and aviation composites experience. He holds a Bachelor’s Degree in Aviation Management from Southern Illinois University and a Masters’ Degree in Aeronautical Engineering from the US Naval Postgraduate School. Greg is a retired Commander with the US Navy, having served 14 years on active duty and 16 years in the reserves as an Aeronautical Engineering Duty officer. He has been a full time and concurrently a part-time contract instructor teaching industry short course in composite repair, repair analysis, manufacturing, laminate design, structural analysis for Abaris Training out of Reno, Nevada. Greg worked for Delta Air Lines for 5 years as the Lead Composite Structures Engineer, and he currently serves on the Composite Materials Handbook committee (CMH-17). Greg is a private pilot and avid sailor.

RYAN HARVEY

ENGINEERING MANAGER

-

Ryan is Engineering Manager and overall responsible for the Engineering Department. Ryan has been with Top Flight since 2012 and is responsible for all CAD development, tool design, and CNC machining. Ryan is an industry leading tool designer. He has expertise in interpretation and development of contoured aircraft structures, reverse engineering using laser scan and CMM data, along with extensive knowledge in the design of various form tools, bond tools, and large-scale assembly fixtures. Ryan has 15+ years of CAD modeling experience in multiple software suites. Prior to working with Top Flight Aerostructures, he worked for 7 years with Vision Composites as a liaison engineer supporting the repair and overhaul of C5 structural components. Ryan holds a Bachelor of Science in Industrial Design from Auburn University. Ryan is an avid soccer player and has been playing since the age of 5, he continues to play in leagues around Atlanta. He is a passionate soccer fan and supports Atlanta United FC and Liverpool FC. In his spare time, Ryan enjoys biking, hiking, and traveling the world whenever possible.

BRIDGET ALLISON

FINANCE MANAGER

bridget.allison@topflightaero.com

-

Bridget is Finance Manager and overall responsible for Accounting and Human Resources. Bridget has been with Top Flight Aerostructures since 2009 and is responsible for cash flow management, accounting, insurance, and all employee administration. Bridget has over 20 years in business management experience. Bridget enjoys spending her free time with family and friends. Most weekends you will find her cheering from the bleachers of her son’s baseball game. Bridget enjoys watching sports and when vacationing she prefers traveling to new destinations.

Contact Us

678-213-1370

Our Office

351 Cadillac Parkway

Dallas, GA, 30157

United States

EMPLOYMENT

CAREER OPPORTUNITIES WITH TOP FLIGHT Aerostructures, Inc.

Top Flight Aerostructures, Inc is accepting applications. All interested applicants are required to complete an employment application. Completed applications should be submitted per the instructions below. Thank you in advance for your interest in Top Flight Aerostructures, Inc.

Candidates must be professional, organized, able to work in a team environment, and self-motivated.

Top Flight Aerostructures is an Equal Opportunity Employer. The company promotes the principle of Equal Employment Opportunity in all employment practices.

Application process

1. Download the Employment Application below. Applicants may also pick-up an application on-site during regular business hours.

2. Complete the application.

3. Return the completed application via email to Human Resources at hr@topflightaero.com

Applicants may also turn in completed applications on-site during regular business hours. Please attach resume or any additional information to the application.

Manufacturer Technician

Currently hiring full-time Manufacturer Technician for small aerospace company in Dallas, GA. Looking for a highly motivated professional that is willing to learn, hardworking, dependable, and have a positive can-do attitude in a winning team environment. Candidate must be highly organized and detail oriented. Position involves following work instructions. Must be able to work with your hands. No prior experience required.

Rate: $12-18/hr + Comprehensive Benefits package.

Must be a U.S. Citizen. Drug test and background check required.

Top Flight Aerostructures is an Equal Opportunity Employer. The company promotes the principle of Equal Employment Opportunity in all employment practices.